In the journey to transform the power generation landscape, the selection of robust components is of utmost importance. Within the context of the CLP Group’s Long Gu Tan Power Station transformation project, the introduction of Songjiang Pump Rubber Expansion Joints, courtesy of Shanghai Songjiang Shock Absorber Company, emerges as a game-changing solution. These Pump rubber expansion joints offer a multitude of advantages, tailored to meet the unique demands of large-scale industrial environments.

The Long Gu Tan Power Station, located in Tuen Mun, New Territories, Hong Kong, embarked on an ambitious mission to enhance power generation efficiency and wastewater treatment capabilities. Songjiang Pump Rubber Expansion Joints have risen to the occasion, offering unparalleled benefits to this transformative project.

Highlighted features and advantages of Songjiang Pump Rubber Expansion Joints within the framework of the power plant transformation:

Corrosion Resistance: Industrial wastewater and sewage systems typically harbor a variety of chemicals and corrosive agents. Songjiang Pump Rubber Expansion Joints, constructed from top-tier rubber materials like EPDM and Viton, display remarkable resistance to chemical corrosion and the onslaught of acidic or alkaline substances. This ensures longevity and reliable performance, even in corrosive environments.

Temperature Resilience: In the dynamic realm of wastewater treatment, systems may encounter extreme temperature variations. These expansion joints are engineered to withstand both high and low-temperature conditions, ensuring they remain flexible and resilient without becoming brittle or rigid.

Strength and Pressure Endurance: The demands of wastewater treatment systems encompass the management of significant water flows and pressures. Songjiang Pump Rubber Expansion Joints offer the requisite strength and pressure resistance, guarding against leaks and ruptures, thereby preserving system integrity.

Exceptional Flexibility: Designed to accommodate system movements, such as bending and deformation, these expansion joints effectively address factors like vibrations, temperature fluctuations, and seismic activity. Their flexibility minimizes the risk of stress concentration and the subsequent risk of breakage.

Wear Resistance: Considering the presence of abrasive particles in wastewater, these expansion joints are engineered for wear resistance, ensuring an extended lifespan and reduced maintenance costs.

Ease of Installation and Maintenance: In large-scale industrial settings, convenience in installation and maintenance is paramount. Songjiang Pump Rubber Expansion Joints are designed to minimize downtime and maintenance expenses.

Regulatory Compliance: Songjiang Pump Rubber Expansion Joints conform to local and international regulations and standards, encompassing material properties, performance standards, and durability. This ensures their compliance with regulations and safety standards within wastewater treatment and sewage discharge systems.

The authentic photo of songjiang Pump Rubber Expansion Joints for Power Plant Transformation

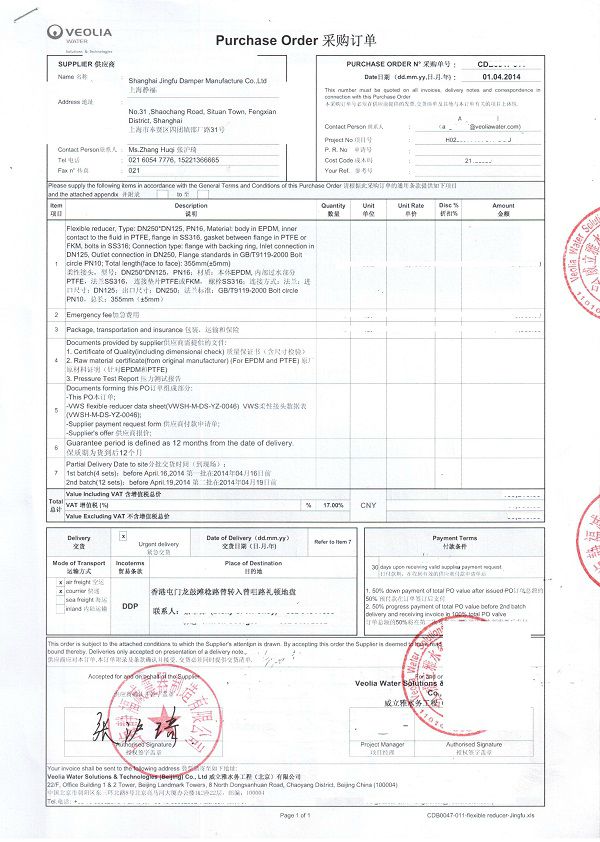

Below is a scanned copy of the authentic agreement. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion, the incorporation of Songjiang Pump Rubber Expansion Joints, provided by Shanghai Songjiang Shock Absorber Company, within the CLP Group’s Long Gu Tan Power Station transformation project demonstrates the significant impact of innovative solutions in large-scale industrial settings. These expansion joints offer adaptability, durability, and a multitude of benefits that enhance the efficiency and reliability of power generation and wastewater treatment.

Related links:[NR] Concentric reducing water pump rubber expansion joints for air conditioning water

![[NR] Single sphere Water Pump Rubber Expansion Joints “Cooling pump of hydropower unit”](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-1-21.jpg&h=300&w=400&zc=1)

![[PVC] Single sphere water Pump Rubber Expansion Joints](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-13.jpg&h=300&w=400&zc=1)

![[FKM] Acid and alkali resistant Water Pump Rubber Expansion Joints](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-14.jpg&h=300&w=400&zc=1)

![[NR] Concentric reducing water pump rubber expansion joints for air conditioning water](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-2-10.jpg&h=300&w=400&zc=1)

![[EPDM] Water Pump Rubber Expansion Joints “Sanjing 4045”](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-1-20.jpg&h=300&w=400&zc=1)