Shanghai Songjiang Vibration Absorber Group Co., Ltd. is a leading provider of pump rubber expansion joints and metal bellows, renowned for its expertise in shock absorption and noise reduction solutions. Collaborating with top-tier automotive component enterprises, Songjiang Group has made significant strides in advancing automotive technology. This case study examines the integration of Metal Bellows in the pump rooms of Suzhou Bosch Automotive Components, highlighting the substantial improvements in performance and reliability brought by this innovation.

Suzhou Bosch Automotive Components: A Leader in Automotive Engineering

Since its establishment in 1999, Suzhou Bosch Automotive Components has been at the forefront of automotive component manufacturing. The company serves as a hub for four Bosch product divisions: Automotive Electronics, Chassis Control, Automotive Multimedia, and PA-ATMO3 – Equipment Manufacturing. Suzhou Bosch has earned a reputation for excellence, securing TS 16949 quality system certification and being recognized as a high-tech enterprise. The company’s R&D technology center in Xinglong Street is celebrated as a key R&D center by the Jiangsu provincial government.

Songjiang Metal Bellows: A Key Component in Pump Room Efficiency

Songjiang Metal Bellows are essential in various industrial applications, including automotive manufacturing, due to their ability to handle temperature and pressure fluctuations. In the context of a pump room,Songjiang Metal Bellows serve crucial functions. They absorb vibrations caused by pump operations, reducing noise and preventing mechanical stress on the piping systems. This ensures the longevity and reliability of the entire system.Songjiang Metal Bellows also accommodate axial, lateral, and angular movements, which are critical in maintaining the integrity of the pump room’s infrastructure.

Case Study: Suzhou Bosch’s Integration of Songjiang Metal Bellows in Pump Rooms

Suzhou Bosch Automotive Components has effectively incorporated Metal Bellows into its pump rooms, resulting in marked improvements in efficiency and durability. These bellows play a pivotal role in compensating for thermal expansion and contraction within the piping systems, ensuring seamless operation under varying temperature conditions. By mitigating vibrations and noise, Metal Bellows enhance the working environment and contribute to the overall operational efficiency of the pump rooms.

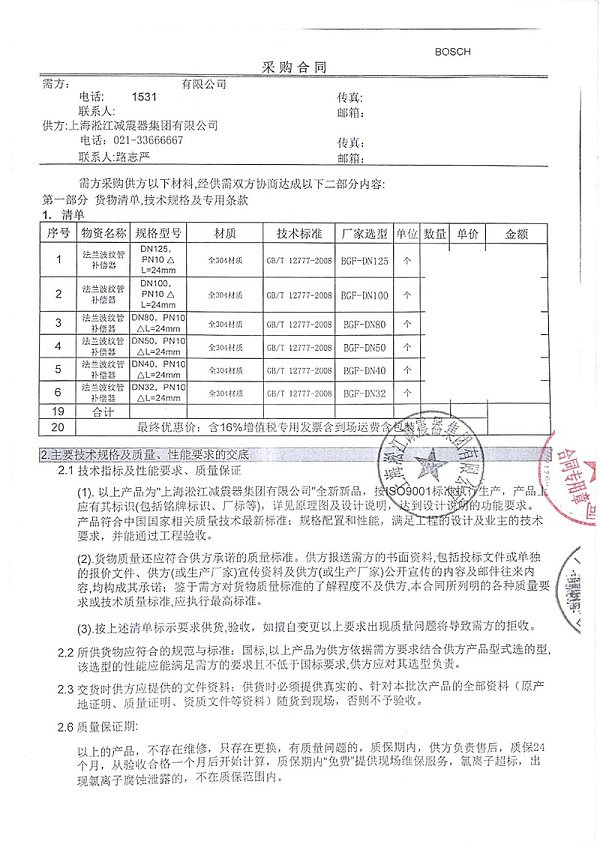

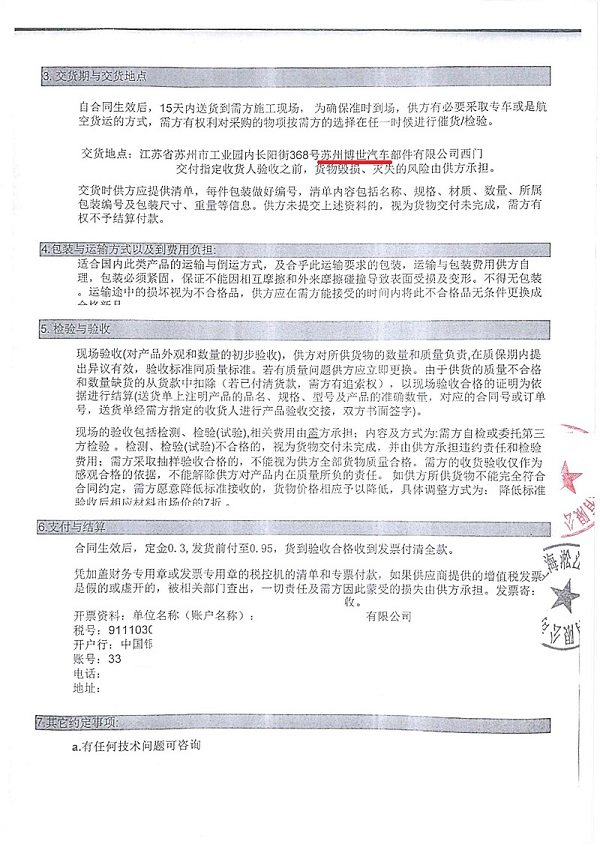

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

Moreover, Metal Bellows in Suzhou Bosch’s pump rooms facilitate the absorption of pressure surges, safeguarding the piping systems from potential damage. This capability is particularly crucial in maintaining the stability and performance of the pump systems, thereby ensuring uninterrupted production processes.

Related links:BGF Pipe damping metallic expansion Joint

![[Galvanized] galvanized flange Water Pump Rubber Expansion Joints “3-year warranty”](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-16.jpg&h=300&w=400&zc=1)

![[PTFE] ductile flange lined PTFE water Pump Rubber Expansion Joints “suitable for aviation kerosene”](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-1-19.jpg&h=300&w=400&zc=1)

![[SUS 304] stainless steel Water Pump Rubber Expansion Joints of Waterworks](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-17.jpg&h=300&w=400&zc=1)

![[NBR] Concentric reducing Oil resistant Water Pump Rubber Expansion Joints](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-1-12.jpg&h=300&w=400&zc=1)

![[Installation site] injection molding machine hydraulic pump oil pumping pump station rubber expansion joint](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Pump-Station-Rubber-Expansion-Joint-2-19.jpg&h=300&w=400&zc=1)

![[Contract for Corrugated Compensators of BASF Zhanjiang Integrated Base Project]](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2025/02/corrugated-compensator-1.jpeg&h=300&w=400&zc=1)