As a renowned beverage manufacturing enterprise, the Hangzhou Pepsi Factory prioritizes not only product quality but also the efficiency and stability of its production processes. In fulfilling this objective, the pump room plays a pivotal role. To meet the factory’s requirements, Shanghai Songjiang Group produces and supplies a series of high-quality pump rubber expansion joints for pumps, providing crucial support for the production processes at the Hangzhou Pepsi Factory.

Characteristics of Shanghai Songjiang Group Rubber Joints for Pumps:

Corrosion Resistance: Songjiang rubber joints for pumps are made from high-quality rubber and stainless steel materials, boasting excellent corrosion resistance. They can withstand the corrosion from various beverage ingredients and additives, ensuring product safety and stability.

Flexibility: These rubber joints exhibit outstanding elasticity and flexibility, adapting to changes in various pipelines and vibrations in the pump room, thereby maintaining the stable operation of the pump system.

Wear Resistance: Considering the high-frequency usage during production, Songjiang rubber joints for pumps are made from wear-resistant rubber materials, capable of maintaining optimal working conditions for extended periods, thus reducing the frequency of replacements and maintenance and improving production efficiency.

Leak Prevention: With a well-designed sealing structure and connection method, these joints ensure a tight connection with the pipeline, effectively preventing leakage and enhancing the safety and stability of the production process.

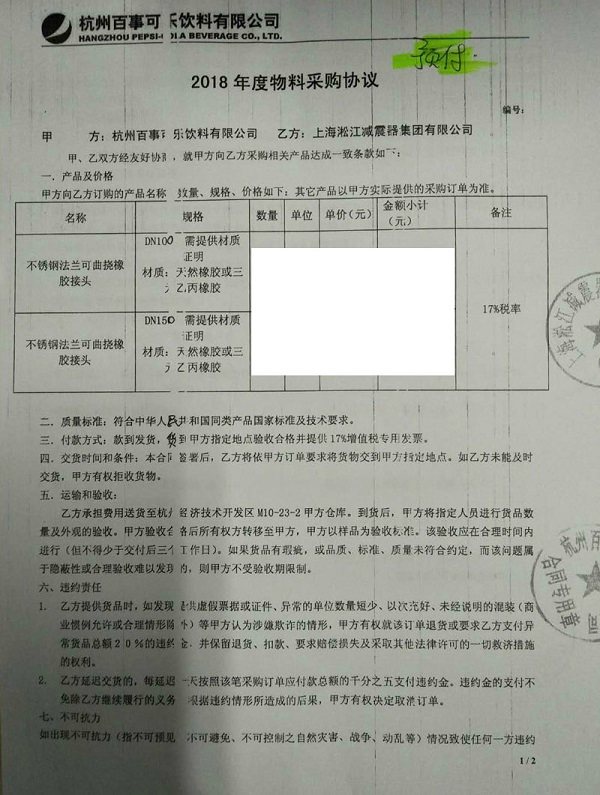

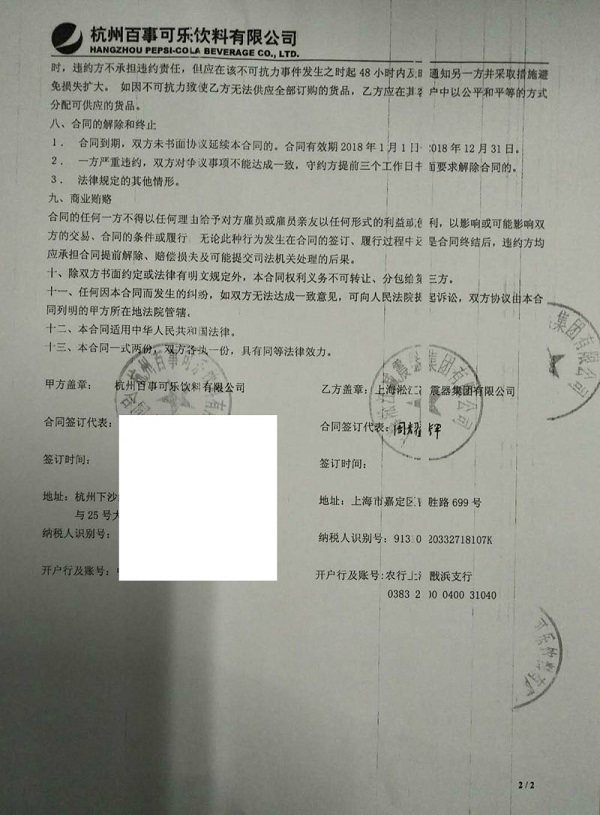

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

Roles of Shanghai Songjiang Group Rubber Joints for Pumps:

Liquid Conveyance: These rubber joints effectively transport various beverage ingredients and additives to different segments of the production line, ensuring the continuity and efficiency of the production process;Pressure Control: Through flexible rubber joints, the pump room can precisely control the pressure in the pipeline, ensuring that products are conveyed and processed at the appropriate pressure during production.; Mixing and Agitation: The flexible design of rubber joints reduces pipeline vibration and fluctuations, facilitating the mixing and agitation of various ingredients and additives to ensure the accuracy and uniformity of product formulations;Cleaning and Sterilization: The corrosion resistance and leak prevention capabilities of these rubber joints make them ideal for cleaning and sterilizing pipelines and equipment, ensuring product safety and hygiene standards.

Related links:[SUS 304] stainless steel Water Pump Rubber Expansion Joints of Waterworks

![[ANSI] Water Pump Rubber Expansion Joints “Physical factory”](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-1-18.jpg&h=300&w=400&zc=1)

![[SUS] stainless steel flange double sphere water pump rubber expansion Joints](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-11.jpg&h=300&w=400&zc=1)

![[Reinforced] double sphere water pump rubber expansion Joints with control tie rods](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-10.jpg&h=300&w=400&zc=1)

![[NBR] double sphere oil resistant water pump rubber expansion Joints](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-12.jpg&h=300&w=400&zc=1)

![[Threaded] Double ball water pump rubber expansion Joints”noise reduction”](https://pump-rubber-expansion-joint.com/wp-content/themes/xsding.sj/timthumb.php?src=https://pump-rubber-expansion-joint.com/wp-content/uploads/2022/06/Water-Pump-Rubber-Expansion-Joints-2-12.jpg&h=300&w=400&zc=1)